News navigation

Recommended news

- [2024-12-24]

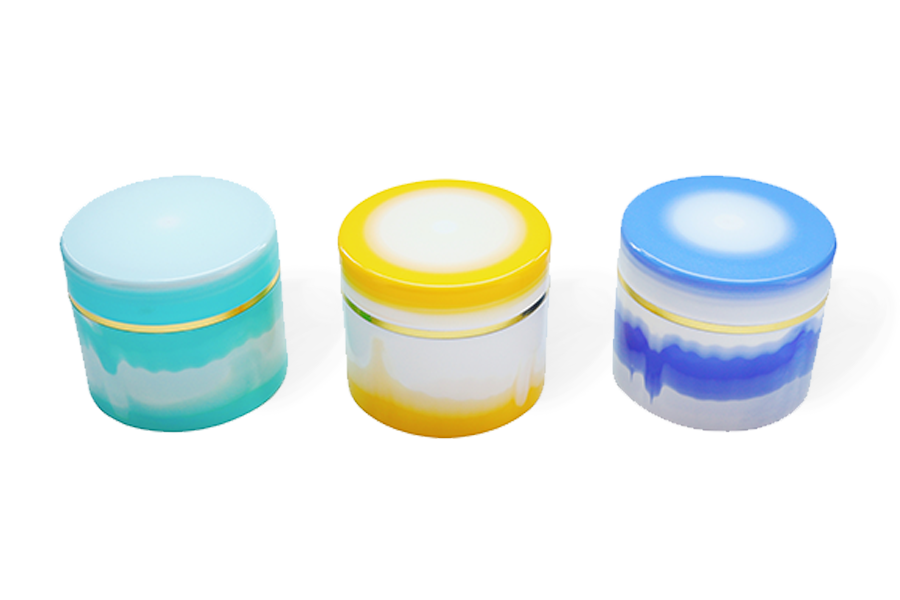

What are the main uses of PP cream jar

PP cream jar, also known as a cream container made of polypropylene material, has a wide range of applications, mainly reflected in the following aspects: 1. Skincare packaging Face cream: face cream is thick and needs to be stored in a container with good sealing. PP cream can provide a reliable sealing environment to prevent face cream from oxidation and deterioration due to contact with

- [2024-12-10]

Application of PCR regenerated materials in the construction industry

PCR (Post Consumer Recycled) recycled materials refer to materials that are recycled and reused after consumption, and have many applications in the construction industry 1、 Application of wall materials 1. Block material PCR recycled materials can be used to manufacture concrete blocks. For example, by mixing PCR recycled materials such as waste plastics and fiberglass with cement, sand,

- [2024-12-03]

What is the function of PP cream jar

The PP cream jar (polypropylene cream jar) mainly has the following functions: 1. Protect the contents Physical protection PP cream cans have certain strength and toughness, which can effectively prevent cream products from being damaged by compression, collision during transportation, storage, and use. For example, during the transportation of products from the production workshop to the

- [2024-11-26]

Application of PET plastic bottles in cosmetic packaging

PET plastic bottles have many applications in cosmetic packaging, and the following are some common aspects: 1. Skincare category: Lotion bottle: PET plastic bottle has good chemical stability, which can prevent the components in lotion from reacting with the bottle body, and ensure that the quality and performance of lotion will not be affected. Its high transparency can clearly show the t

- [2024-11-19]

Application of PET plastic bottles in pharmaceutical packaging

PET plastic bottles have many applications in pharmaceutical packaging, mainly including the following aspects: 1. Oral medication packaging: Oral liquid preparations: such as cough syrup, cold oral liquid and other liquid medicines, PET plastic bottles are common packaging containers. Its advantage is that the bottle body is transparent, making it convenient for patients and medical staff

- [2024-11-12]

What are the application industries of PCR regenerated materials

The application industry of PCR regenerated materials is wide, as follows: 1. Automotive industry: Interior components: can be used to manufacture interior parts of automobiles, such as instrument panels, door panels, seat materials, interior decorative strips, etc. Compared to native plastics, PCR recycled materials not only meet the performance requirements of interior parts, but also re

- [2023-05-05]

The six major development trends of plastic packaging are more environmentally friendly

Plastic packaging will move towards lightweight, reducing packaging weight. Lightweight refers to using less information to produce packaging and reduce weight, which is profitable for the environment and enterprises. Generally, in the plastic packaging industry, containers such as plastic pallets, bottles, cans, hoses, and caps are simpler to achieve weight reduction.

- [2023-05-05]

The Future Development of PCR Plastics

In order to reduce the energy consumption and carbon emissions of disposable plastics, DOE of the United States Department of Energy recently announced that it will provide US $13.4 million for the next generation of plastic technology.

- CHANGSHU SHINE PLASTIC INDUSTRY CO.,LTD Phone:0512-52557888 Mailbox:shenshisuye@163.com Company address:No. 20 Guangyuan Road, South Development Zone, Zhitang Town, Changshu City, Jiangsu Province

-

Scan your phone

Scan your phone

wechat number:

wechat number:

home

home

WeChat

WeChat

telephone

telephone