You Are Here:Home > News Center

> Industry Dynamics

News navigation

Recommended news

What are the applications of PCR regenerated materials in the automotive industry

source:m.xiaosenv.cn | Release time:2024-12-31

The application of PCR regenerated materials in the automotive industry is mainly reflected in the following aspects:

1. Interior components

Dashboard: The dashboard is made of PCR recycled materials, such as polypropylene (PP) or acrylonitrile butadiene styrene copolymer (ABS) containing PCR components, which have good impact resistance and dimensional stability, and can meet the performance requirements of the dashboard during long-term use, while reducing production costs and dependence on native materials.

Center console bracket: Nordic Chemicals' Borcycle GD3600SY product contains 30% glass fiber and almost all polymer parts are made of post consumer recycled PP, which is used for the center console bracket of the new Peugeot 3008. This is the first time that 65% PCR PP has been used in large-scale automotive interior production.

Seat interior: Some car companies use recycled materials made from polyester fibers in plastic bottles to create seat interiors, which are not only comfortable and beautiful, but also have good breathability and wear resistance, while reducing the pollution of waste plastic bottles to the environment.

Door inner panel: PCR regenerated materials can be used to manufacture door inner panels, such as regenerated PP and other materials. Through modified injection molding and other processes, it has sufficient strength and flexibility to withstand the impact force of opening and closing doors in daily use. It can also be surface treated according to design requirements, such as customization of texture, color, etc.

2. Exterior components

Bumper: It is one of the common components in car exterior that uses PCR recycled materials, usually made of recycled PP or recycled PC/ABS alloy. After modification, these materials have good impact resistance, weather resistance, and surface glossiness, which can effectively absorb energy during collisions, protect the safety of the vehicle and passengers, while reducing the weight of the vehicle and improving fuel economy.

Body coverings: Some car manufacturers have begun to try using high-performance recycled materials such as PCR carbon fiber to manufacture body coverings, such as engine hood, trunk lid, etc. PCR carbon fiber has the characteristics of lightweight and high strength, which can significantly reduce the weight of the vehicle without reducing its strength and safety, thereby improving the acceleration performance, handling performance, and range of the vehicle, especially suitable for electric vehicles and high-performance sports cars.

3. Functional components

Battery casing: With the popularity of electric vehicles, the demand for battery casings is also increasing. PCR regenerated materials can be used to manufacture battery casings, such as regenerated polycarbonate (PC) and other materials, which have good insulation properties, heat resistance, and mechanical strength. They can effectively protect battery packs from external environmental influences, ensuring the safe and stable operation of batteries.

Engine compartment components: such as engine hood and intake manifold can also use PCR regenerated materials. These components typically require high temperature resistance, corrosion resistance, and good mechanical properties. By modifying and optimizing PCR regenerated materials, they can meet the harsh working environment requirements of the engine compartment, while reducing the weight of engine compartment components and improving engine efficiency and fuel economy.

4. Packaging for car maintenance products

Delian Group adopts Dow REVOLOOP ? Recycled plastic resin (PCR) has been successfully applied to automotive maintenance packaging, such as lubricant bottles, antifreeze bottles, etc. This not only significantly reduces reliance on native resins and lowers the carbon footprint of packaging, but also provides a more environmentally friendly packaging solution for the automotive maintenance market.

1. Interior components

Dashboard: The dashboard is made of PCR recycled materials, such as polypropylene (PP) or acrylonitrile butadiene styrene copolymer (ABS) containing PCR components, which have good impact resistance and dimensional stability, and can meet the performance requirements of the dashboard during long-term use, while reducing production costs and dependence on native materials.

Center console bracket: Nordic Chemicals' Borcycle GD3600SY product contains 30% glass fiber and almost all polymer parts are made of post consumer recycled PP, which is used for the center console bracket of the new Peugeot 3008. This is the first time that 65% PCR PP has been used in large-scale automotive interior production.

Seat interior: Some car companies use recycled materials made from polyester fibers in plastic bottles to create seat interiors, which are not only comfortable and beautiful, but also have good breathability and wear resistance, while reducing the pollution of waste plastic bottles to the environment.

Door inner panel: PCR regenerated materials can be used to manufacture door inner panels, such as regenerated PP and other materials. Through modified injection molding and other processes, it has sufficient strength and flexibility to withstand the impact force of opening and closing doors in daily use. It can also be surface treated according to design requirements, such as customization of texture, color, etc.

2. Exterior components

Bumper: It is one of the common components in car exterior that uses PCR recycled materials, usually made of recycled PP or recycled PC/ABS alloy. After modification, these materials have good impact resistance, weather resistance, and surface glossiness, which can effectively absorb energy during collisions, protect the safety of the vehicle and passengers, while reducing the weight of the vehicle and improving fuel economy.

Body coverings: Some car manufacturers have begun to try using high-performance recycled materials such as PCR carbon fiber to manufacture body coverings, such as engine hood, trunk lid, etc. PCR carbon fiber has the characteristics of lightweight and high strength, which can significantly reduce the weight of the vehicle without reducing its strength and safety, thereby improving the acceleration performance, handling performance, and range of the vehicle, especially suitable for electric vehicles and high-performance sports cars.

3. Functional components

Battery casing: With the popularity of electric vehicles, the demand for battery casings is also increasing. PCR regenerated materials can be used to manufacture battery casings, such as regenerated polycarbonate (PC) and other materials, which have good insulation properties, heat resistance, and mechanical strength. They can effectively protect battery packs from external environmental influences, ensuring the safe and stable operation of batteries.

Engine compartment components: such as engine hood and intake manifold can also use PCR regenerated materials. These components typically require high temperature resistance, corrosion resistance, and good mechanical properties. By modifying and optimizing PCR regenerated materials, they can meet the harsh working environment requirements of the engine compartment, while reducing the weight of engine compartment components and improving engine efficiency and fuel economy.

4. Packaging for car maintenance products

Delian Group adopts Dow REVOLOOP ? Recycled plastic resin (PCR) has been successfully applied to automotive maintenance packaging, such as lubricant bottles, antifreeze bottles, etc. This not only significantly reduces reliance on native resins and lowers the carbon footprint of packaging, but also provides a more environmentally friendly packaging solution for the automotive maintenance market.

Previous:

period

Next:

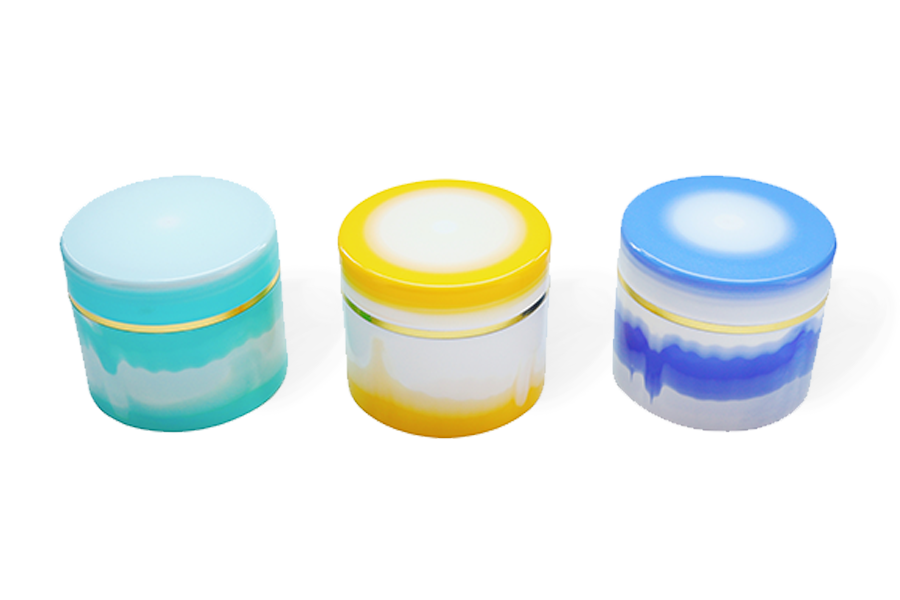

What are the main uses of PP cream jar

【Related articles】

【Related Products】

- CHANGSHU SHINE PLASTIC INDUSTRY CO.,LTD Phone:0512-52557888 Mailbox:shenshisuye@163.com Company address:No. 20 Guangyuan Road, South Development Zone, Zhitang Town, Changshu City, Jiangsu Province

-

Scan your phone

Scan your phone

wechat number:

wechat number:

home

home

WeChat

WeChat

telephone

telephone